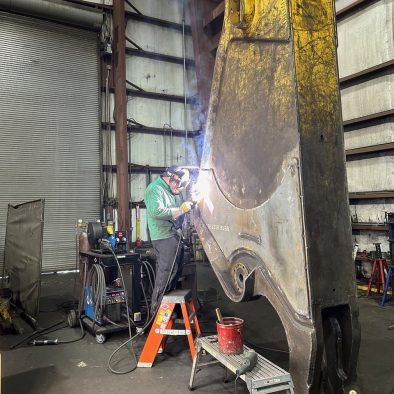

With over 35 years of experience, J.R. Smith Welding Service, Inc. specializes in catastrophic failure repairs, maintenance, and reconditioning for all types of scrap metal processing machinery—particularly the demanding service of mobile hydraulic metal shear restoration.

Our AWS D1.1 certified structural welding expertise, paired with professionally engineered repair procedures, allows us to weld and machine steel plates and structural components up to 10 inches thick on a routine basis. We deliver exceptional workmanship and durability to keep these high-value attachments performing in the most punishing conditions of the metal processing industry.

Our labor-intensive reconditioning services not only restore operational integrity but also extend the life of costly equipment—often at a fraction of the cost of new replacement—offering a strong return on investment. All work is warranted for durability, proper fit, and reliable operation.

We proudly serve industries across Pennsylvania, New Jersey, New York, Delaware, and Maryland, with the ability to travel further when specialized, certified repair solutions are needed.

Our services include:

- Heavy structural welding repairs and hydraulic realignment of broken jaws

- General crack welding repairs

- Magnetic particle inspections

- Weld build-up of worn knife and jaw plate surfaces

- Fabrication and installation of severe-service plate kits

- Weld build-up and re-machining of worn blade mounting surfaces

- Welding and re-drilling cracked or oblong blade and knife bit bolt holes

- Welding repairs to broken internal diaphragms and supporting plate work

- Removal of broken bolts and threaded hole repairs

- Weld build-up, line boring, and facing of pivot pins, bushing bores, hydraulic cylinder mounts, and rod eyes

- 150-ton portable hydraulic pressing for pin and bushing installation/removal

- Liquid nitrogen shrink-fitting of large parts

- Exothermic cutting and piercing